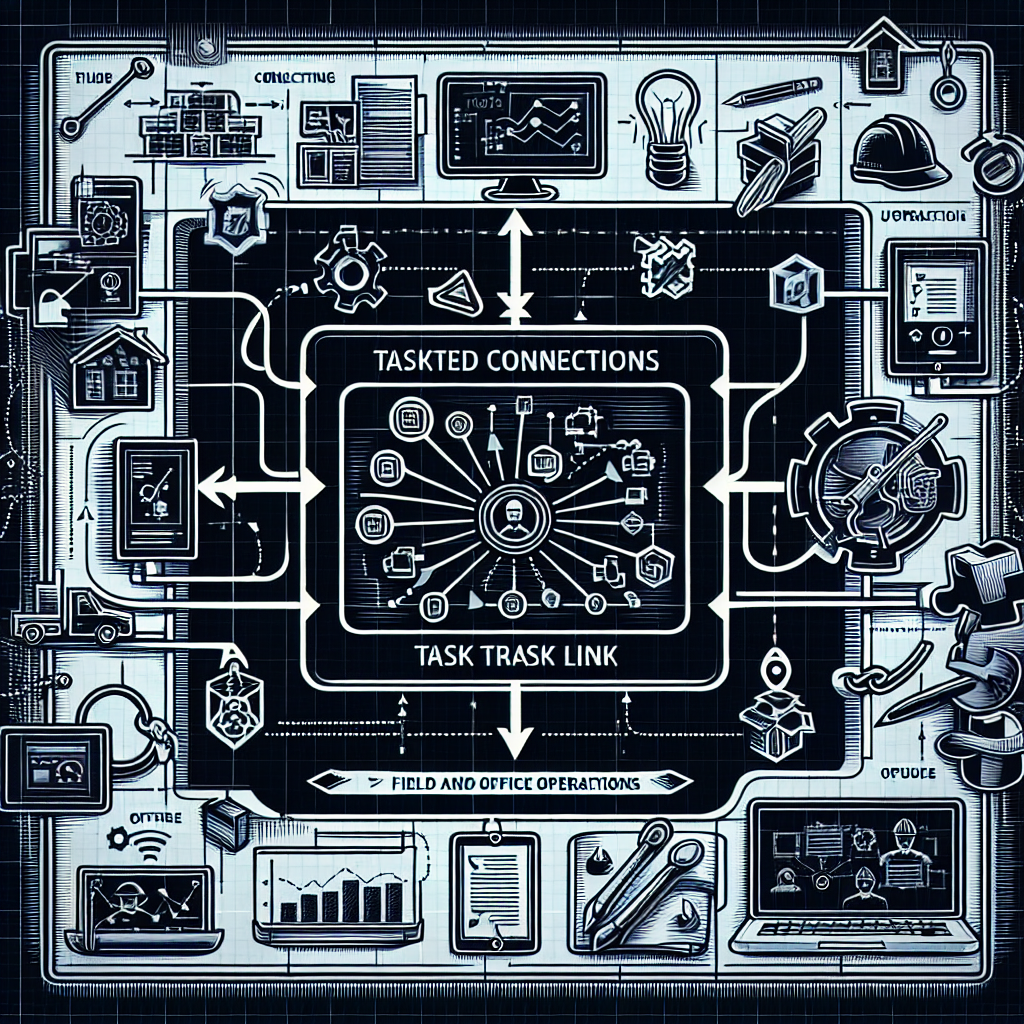

The integration of digital tools within the Smart Manufacturing and Robotics sectors has become paramount for enhancing operational efficiency. Recent advancements, such as the launch of Task Link by Bluebeam, exemplify this trend. Task Link serves as a native integration between Bluebeam Revu and GoCanvas, which facilitates real-time task updates, field data capture, and centralized documentation. This integration is particularly pertinent for industrial technologists, who must navigate the complexities of aligning office and field workflows to maximize productivity and minimize errors.

The primary goal of the Task Link integration is to bridge the communication gap between planning and execution phases in manufacturing projects. This can be achieved through the seamless transfer of tasks from the office to field teams, ensuring that all stakeholders possess real-time updates on project status. By leveraging Task Link, organizations can enhance their project management capabilities, thereby improving overall workflow efficiency.

It is important to note that Task Link is accessible only to Bluebeam subscribers with an active GoCanvas subscription, which may limit accessibility for some organizations.

As the Smart Manufacturing and Robotics industries continue to evolve, the integration of artificial intelligence (AI) will play a crucial role in further enhancing tools like Task Link. Future advancements may include AI-driven analytics that can predict project delays or resource shortages based on real-time data captured in the field. This would not only improve decision-making processes but also enable proactive adjustments to project plans. Moreover, as AI technology becomes more sophisticated, it could facilitate more complex task management functions, such as automated task prioritization and optimization based on historical project performance data.

Disclaimer

The content on this site is generated using AI technology that analyzes publicly available blog posts to extract and present key takeaways. We do not own, endorse, or claim intellectual property rights to the original blog content. Full credit is given to original authors and sources where applicable. Our summaries are intended solely for informational and educational purposes, offering AI-generated insights in a condensed format. They are not meant to substitute or replicate the full context of the original material. If you are a content owner and wish to request changes or removal, please contact us directly.

Source link :