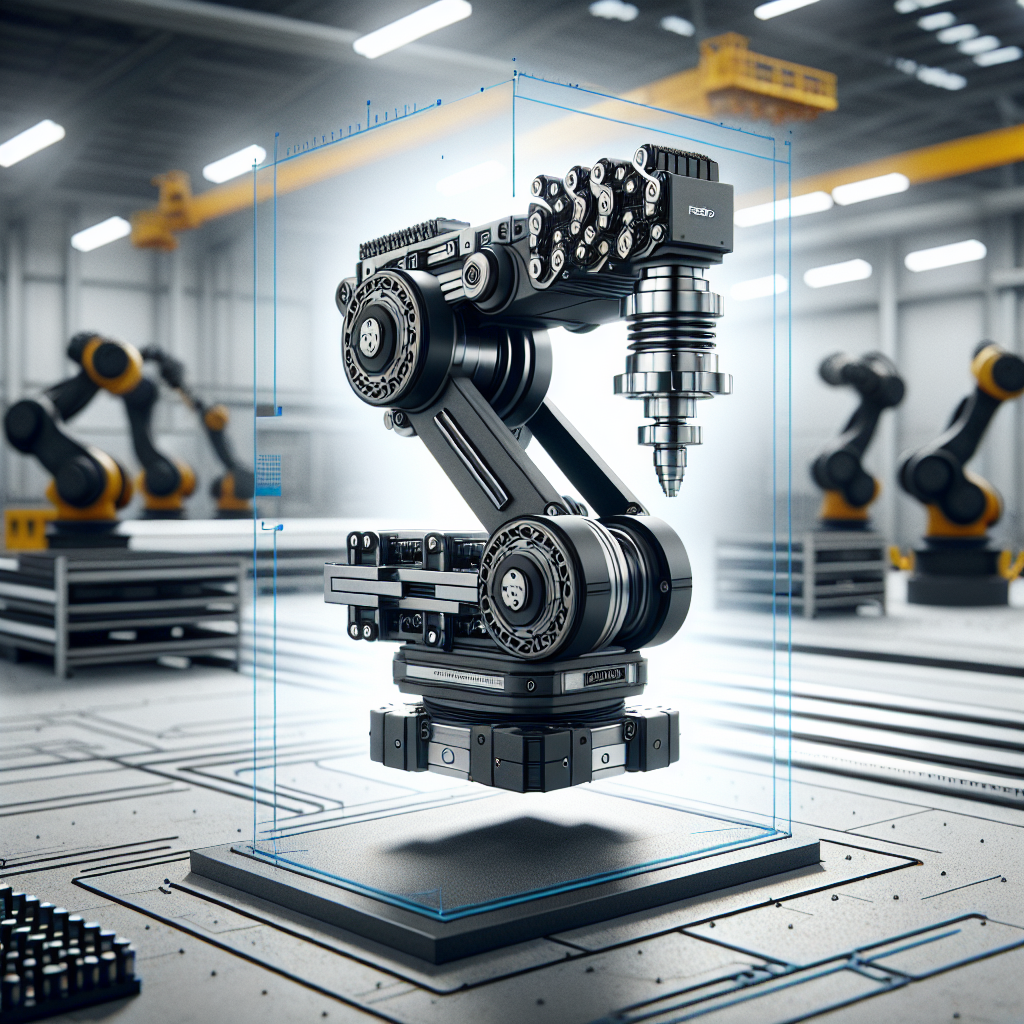

The integration of robotics in manufacturing processes has revolutionized operational efficiency, particularly in sectors such as food, pharmaceuticals, and cosmetics. The recent introduction of the Festo HPSX compliant gripper exemplifies advancements in robotic technologies aimed at enhancing product handling and manipulation. Designed specifically for delicate and hygienically sensitive items, the HPSX gripper addresses long-standing challenges associated with traditional rigid gripping solutions. Its ability to adapt to various object shapes and sizes marks a significant evolution in compliant gripper technology, which is crucial in environments where automation demands precision and care.

The primary objective of the Festo HPSX gripper is to facilitate the automation of handling delicate products without causing damage. This goal is achieved through a pneumatic design that employs soft, silicone-based materials capable of conforming to the contours of different objects, thereby reducing the risk of product damage and contamination. In addition, the HPSX gripper’s design optimizes gripping force while minimizing air volume, enabling faster and more efficient picking processes. This innovation is particularly beneficial in industries where product integrity is paramount, such as food handling and pharmaceuticals.

While the HPSX gripper offers numerous advantages, certain limitations must be acknowledged. Its performance can be influenced by external factors such as temperature extremes, the surface characteristics of the handled objects, and operational speeds that may induce excessive wear. Furthermore, while the standard model does not include haptic sensing capabilities, these features may be integrated upon request, which could increase complexity and cost.

The ongoing developments in artificial intelligence (AI) are poised to significantly influence the capabilities of robotic systems, including grippers like the HPSX. As AI algorithms evolve, they will enable more sophisticated sensory feedback and machine learning capabilities, allowing robots to adapt in real-time to varying operational conditions and object characteristics. This integration promises to enhance the precision and effectiveness of robotic grippers, leading to further advancements in automation across diverse industries. The future may see grippers that not only manipulate objects but also make autonomous decisions based on sensory input, thereby optimizing workflows and minimizing errors in real-time.

Disclaimer

The content on this site is generated using AI technology that analyzes publicly available blog posts to extract and present key takeaways. We do not own, endorse, or claim intellectual property rights to the original blog content. Full credit is given to original authors and sources where applicable. Our summaries are intended solely for informational and educational purposes, offering AI-generated insights in a condensed format. They are not meant to substitute or replicate the full context of the original material. If you are a content owner and wish to request changes or removal, please contact us directly.

Source link :