The semiconductor industry is at a pivotal crossroads, where the challenge of obsolescence significantly impacts manufacturers and users alike. As technology advances, certain semiconductor products become obsolete, often due to shifts in market focus, changes in production methodologies, and evolving performance requirements. This phenomenon is especially relevant in the realm of Smart Manufacturing and Robotics, where Industrial Technologists face the daunting task of ensuring the longevity and reliability of critical components. The intricate interplay of various factors, from business strategies to supply chain dynamics, necessitates a comprehensive approach to mitigate the hidden costs associated with semiconductor obsolescence.

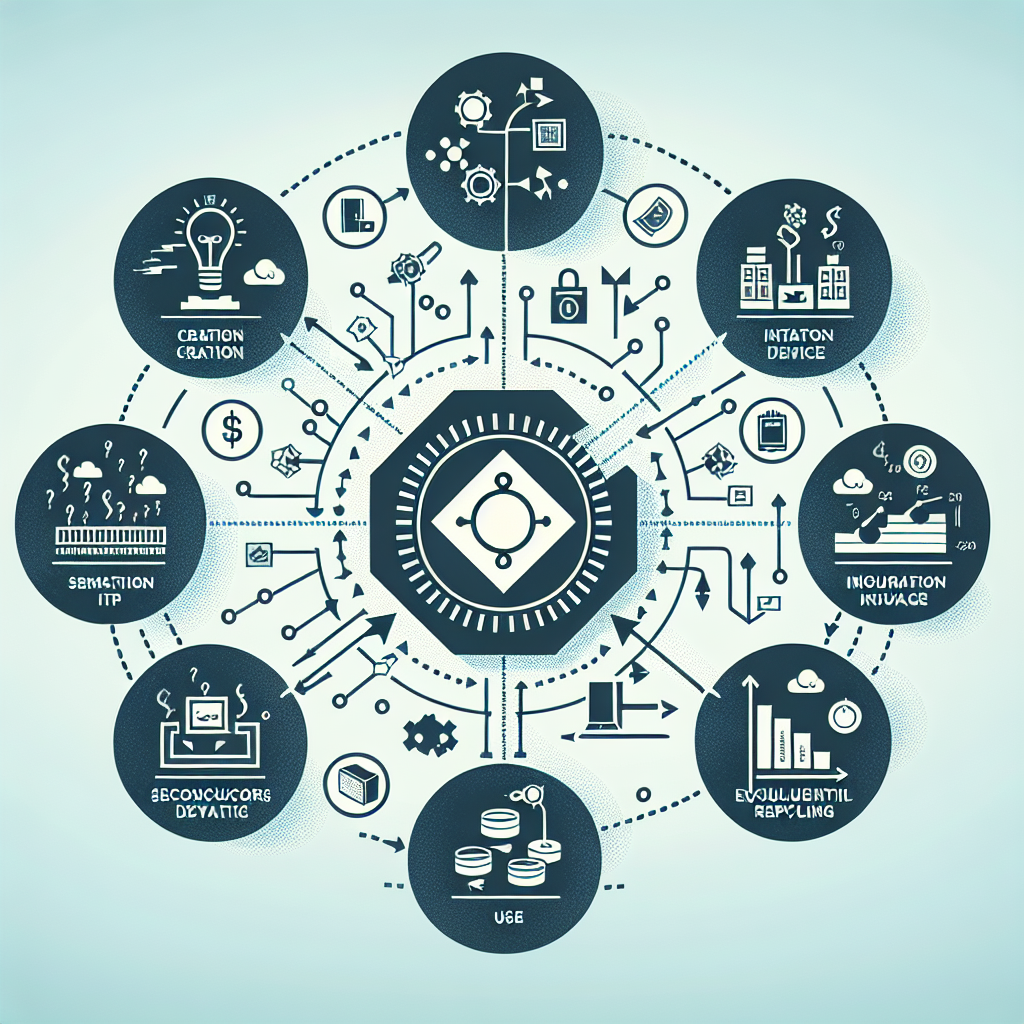

The primary objective is to mitigate the risks associated with semiconductor obsolescence. Achieving this entails a multi-faceted strategy that encompasses effective supply chain management, proactive partnership with licensed semiconductor manufacturers, and a keen understanding of market trends. By addressing these components, Industrial Technologists can ensure the availability of critical semiconductor devices even as the industry landscape shifts.

Several advantages arise from a proactive approach to managing semiconductor obsolescence, which can be substantiated through the original content:

However, it is essential to recognize potential limitations, such as the reliance on existing OSAT (Outsourced Semiconductor Assembly and Test) structures, which may not sustain long-term production volumes. If any link in the OSAT chain becomes economically unfeasible, an obsolescence event is likely to occur.

The future of semiconductor management, particularly within Smart Manufacturing and Robotics, will be profoundly influenced by advancements in artificial intelligence (AI). AI technologies have the potential to enhance predictive analytics, enabling companies to foresee obsolescence events and make informed decisions regarding component management. Furthermore, AI can facilitate the optimization of supply chain logistics, improving efficiency and responsiveness to market demands.

As we move toward an increasingly interconnected manufacturing landscape, AI-driven solutions will likely play a crucial role in monitoring semiconductor health, predicting failures, and automating inventory management. Consequently, Industrial Technologists must remain vigilant to embrace these innovations to stay competitive in a rapidly evolving industry.

Disclaimer

The content on this site is generated using AI technology that analyzes publicly available blog posts to extract and present key takeaways. We do not own, endorse, or claim intellectual property rights to the original blog content. Full credit is given to original authors and sources where applicable. Our summaries are intended solely for informational and educational purposes, offering AI-generated insights in a condensed format. They are not meant to substitute or replicate the full context of the original material. If you are a content owner and wish to request changes or removal, please contact us directly.

Source link :