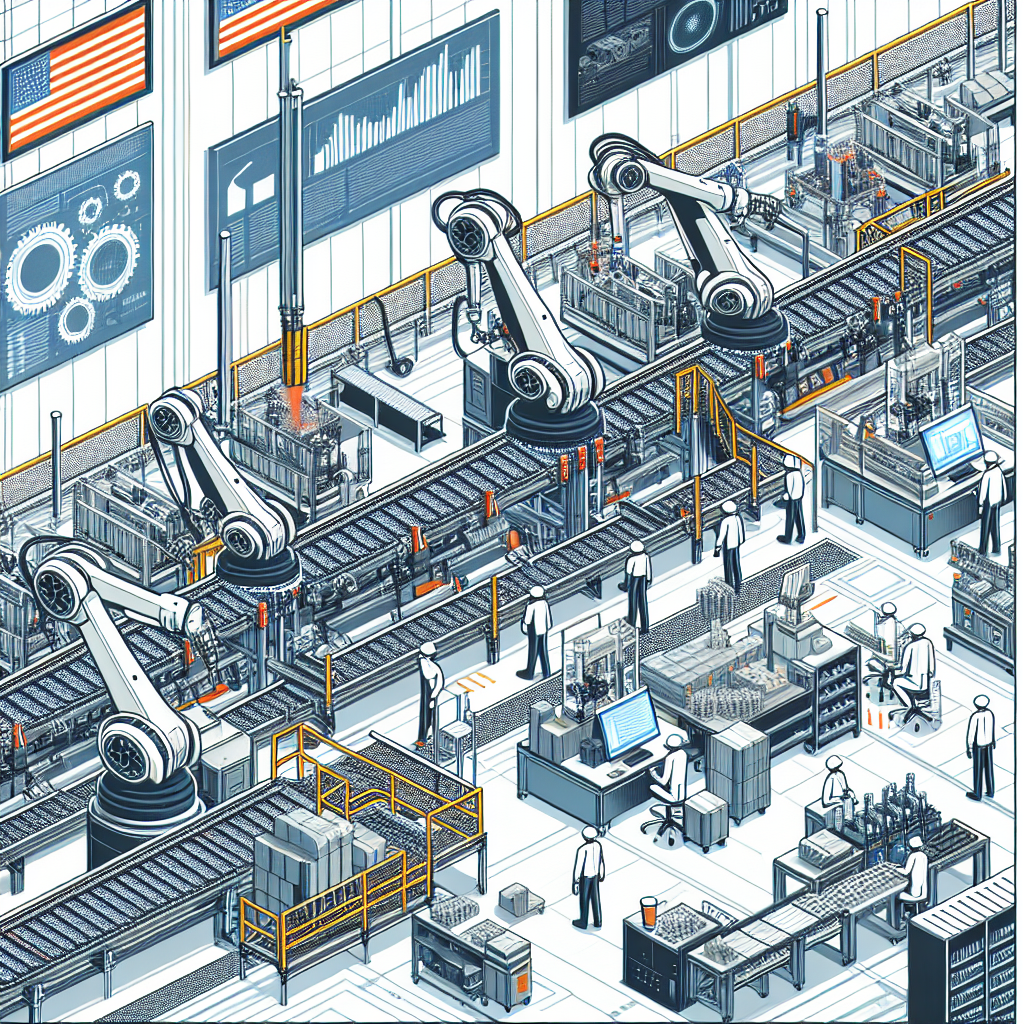

The recent collaboration between Foxconn, a leading contract manufacturer, and Intrinsic, an Alphabet subsidiary focused on robotics development tools, represents a significant advancement in the realm of Smart Manufacturing and Robotics. Announced during Foxconn’s Hon Hai Tech Day in Taipei, this partnership seeks to revolutionize manufacturing processes in the United States by integrating artificial intelligence (AI), robotics, and digital twin technologies into modular automation systems. The aim is to transition Foxconn’s operations from rigid automation paradigms to more flexible, adaptable robotics capable of performing a variety of tasks, including assembly, inspection, machine tending, and logistics.

The primary objective of this alliance is to enhance the efficiency and flexibility of manufacturing operations by deploying AI-driven robotics solutions. Achieving this goal involves the development of modular, AI-enabled robotic workcells tailored to Foxconn’s specific production needs. By leveraging Intrinsic’s advanced robotics software and Foxconn’s extensive manufacturing expertise, the partnership aims to facilitate the rapid deployment of intelligent automation across Foxconn’s facilities. This integration is expected to yield significant improvements in operational efficiency, ultimately enabling high-mix, high-volume production models that are both economically and technically viable.

While the partnership holds substantial promise, several limitations must be acknowledged. The complexity of integrating advanced AI systems with existing manufacturing processes poses challenges that could hinder the speed of implementation. Additionally, reliance on a single technology platform may create vulnerabilities in operational resilience should any unforeseen issues arise with the AI models. Furthermore, the initial investment in developing these advanced robotics systems may be considerable, potentially limiting accessibility for smaller manufacturers.

The implications of ongoing advancements in AI for the manufacturing sector are profound. As AI technologies continue to evolve, the capabilities of robotic systems will expand, enabling more intricate and precise operations that were previously unattainable. These advancements could lead to a paradigm shift in manufacturing, with AI becoming integral to every aspect of production—from design and prototyping to manufacturing and supply chain management. Moreover, as AI systems become more adept at handling complex tasks, the demand for skilled Industrial Technologists will increase, necessitating ongoing education and training in AI and robotics to ensure workforce readiness for the factory of the future.

Disclaimer

The content on this site is generated using AI technology that analyzes publicly available blog posts to extract and present key takeaways. We do not own, endorse, or claim intellectual property rights to the original blog content. Full credit is given to original authors and sources where applicable. Our summaries are intended solely for informational and educational purposes, offering AI-generated insights in a condensed format. They are not meant to substitute or replicate the full context of the original material. If you are a content owner and wish to request changes or removal, please contact us directly.

Source link :